Structural Issues – Two Problems; Two Solutions…

At Crown Construction Solutions we love engineering solutions to building problems. Today’s post is all about two recent projects where a problem was solved with our engineering skills.

Problem 1 – An old property in Cheltenham was suffering with a severe structural issues between the end gable wall of the house and the side walls….yes the gable wall was moving away from the rest of the building. This affected many parts of the building especially over the doorways and on the 1st floor and in the loft space significant movement was apparent especially once the wallpaper had been removed. The problem, which is common on older houses, is the gable wall was not attached to the roof structure in any way. The only good news was the gable wall was constructed of brick and 9 inches thick so it has significant strength and was able to cope with the movement to date. However, if it was left to move further there was a risk of collapse.

Solution – Having consulted the structural engineer we proceeded with our design to construct a steel framework that would attach directly to the outside wall and then be braced across the 1st floor ceiling joists to ensure no further movement was possible. We also fitted some lateral bracing within the roof space and some additional wall ties higher up the gable to ensure no further movement was possible. Please see the pictures below.

Problem 2 – We have been appointed to construct a link building between a house and barn. On the forward elevation, a 4 metre triple glazed sliding door will be fitted and the client wanted an oak beam above to ensure the building retained its character. However, the common issue of long timber facing beams is that they twist over time and end up causes issues and most of all it looks badly finished, despite the beautiful ageing of the oak.

Solution – We designed a structural steel beam that would not only bear the load of the building but also incorporate the oak beam firmly across the 4 metre length. With some careful planning, and drawings submitted to our steel fabricators we ended up with the beam you can see below. You will also notice that we have insulated behind the oak beam as well to ensure this void is totally filled.

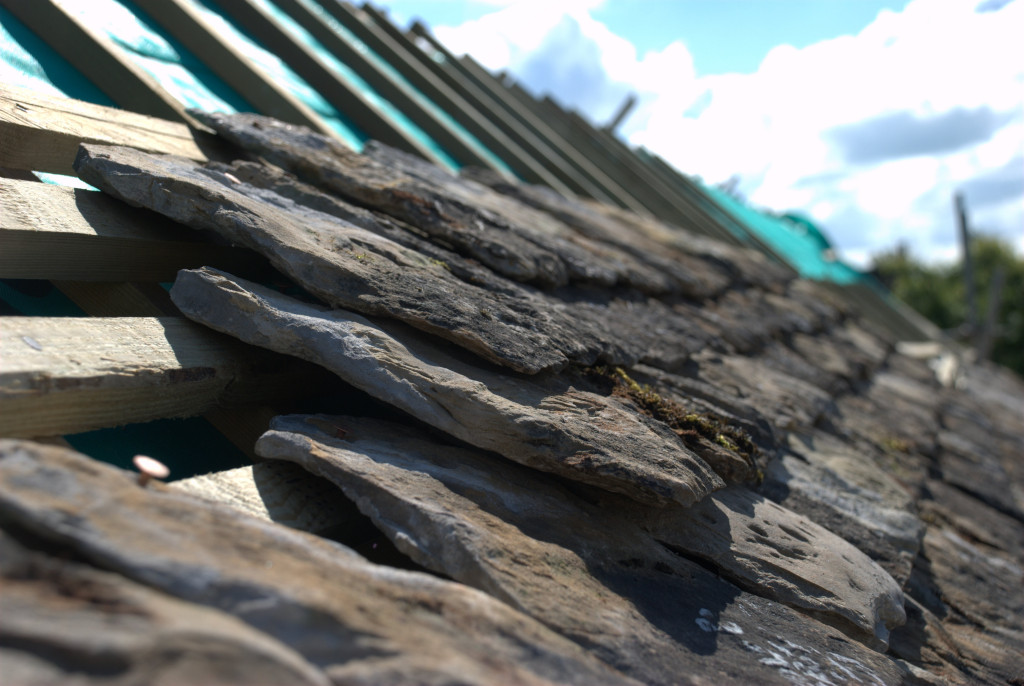

PICTURES FOR PROBLEM 1

PICTURES FOR PROBLEM 2

At Crown Construction Solutions we love engineering solutions to building problems. Today’s post is all about two recent projects where a problem was solved with our engineering skills.

Problem 1 – An old property in Cheltenham was suffering with a severe structural issues between the end gable wall of the house and the side walls….yes the gable wall was moving away from the rest of the building. This affected many parts of the building especially over the doorways and on the 1st floor and in the loft space significant movement was apparent especially once the wallpaper had been removed. The problem, which is common on older houses, is the gable wall was not attached to the roof structure in any way. The only good news was the gable wall was constructed of brick and 9 inches thick so it has significant strength and was able to cope with the movement to date. However, if it was left to move further there was a risk of collapse.

Solution – Having consulted the structural engineer we proceeded with our design to construct a steel framework that would attach directly to the outside wall and then be braced across the 1st floor ceiling joists to ensure no further movement was possible. We also fitted some lateral bracing within the roof space and some additional wall ties higher up the gable to ensure no further movement was possible. Please see the pictures below.

Problem 2 – We have been appointed to construct a link building between a house and barn. On the forward elevation, a 4 metre triple glazed sliding door will be fitted and the client wanted an oak beam above to ensure the building retained its character. However, the common issue of long timber facing beams is that they twist over time and end up causes issues and most of all it looks badly finished, despite the beautiful ageing of the oak.

Solution – We designed a structural steel beam that would not only bear the load of the building but also incorporate the oak beam firmly across the 4 metre length. With some careful planning, and drawings submitted to our steel fabricators we ended up with the beam you can see below. You will also notice that we have insulated behind the oak beam as well to ensure this void is totally filled.

PICTURES FOR PROBLEM 1

PICTURES FOR PROBLEM 2